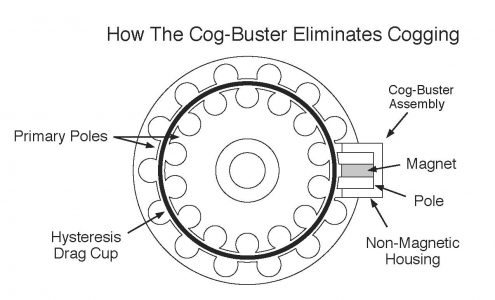

How the Placid Cog-Buster Eliminates Cogging

Hysteresis Brakes: Torque Without Physical Contact

The coil produces a magnetic field while the primary pole structure directs and concentrates the magnetic field. The rotating hysteresis drag cup is connected to the output shaft which is supported by ball bearings. The primary pole structure produces alternating polarity tangentially magnetizing sections in the drag cup. As the shaft rotates, the magnetized sections move around the cup. The interaction of the magnetized sections in the cup and the magnetic field from the stationary primary pole structure provides the drag torque. The torque is proportional to input current and independent of RPM. Full torque is available even at zero RPM.

What is Cogging

If the input current is brought to zero while the shaft is stopped, there will be magnetized sections in the cup due to residual magnetism. These magnetic sections try to align with the poles, just like a steel bar will try to align between the two ends of a horseshoe magnet. This causes cogging (pulsating output torque). Without the Cog-Buster the brake will cog forever at the zero or lower torque setting until manually decogged.

Placid Industries Improvement Erases Cogging

For hysteresis brake sizes H11 and larger the Cog-Buster device stops the cogging within one revolution of the shaft/drag cup assembly. The permanent magnet and two poles produce a uni-directional tangential magnetic field in the cup, directly between the poles. Turning the shaft one turn exposes the entire periphery of the cup to the unidirectional field, erasing all the magnetic sections in the drag cup which stops the cogging.