How To Size Hysteresis Brakes

Click to Expand A hysteresis brake is a specialized device that utilizes magnetic fields to transfer torque from one shaft to another. The coil produces a magnetic field while the primary pole structure directs and concentrates the magnetic field. The rotating hysteresis drag cup is connected to the output shaft which is supported by ball…

Read more Tensioning with Magnetic Particle Brakes & Clutches

How to build precise unwinding/rewinding systems using simple, easy to use technology. Magnetic particle brakes can provide an adjustable braking tension for unwinding film, wire or any web. Magnetic particle clutches can provide an adjustable tension for rewinding the same. Simple, effective tensioning systems can easily be built when each are teamed with a D.C.…

Read more Placid Industries eBook – Magnetic Particle vs Hysteresis Brakes

Which is better for your application – Magnetic Particle or Hysteresis Brakes? This eBook from Placid Industries will explore the characteristics of each brake technology and give application examples showing where each may or may not work the best. The best choice for you depends on the details of your application and often either type…

Read more Magnetic Particle Brakes for Packaging or Labeling Machines

Precision tension control is needed for many types of packaging or labeling machinery. Stretch-wrap machines wrap thin plastic around boxes stacked tall on a pallet, to keep the boxes secure and prevent movement during shipping. Automatic machines also apply plastic labels or film from a large supply roll onto drink containers or other food and…

Read more How the Placid Cog-Buster Eliminates Cogging

The coil produces a magnetic field while the primary pole structure directs and concentrates the magnetic field. The rotating hysteresis drag cup is connected to the output shaft which is supported by ball bearings. The primary pole structure produces alternating polarity tangentially magnetizing sections in the drag cup. As the shaft rotates, the magnetized sections…

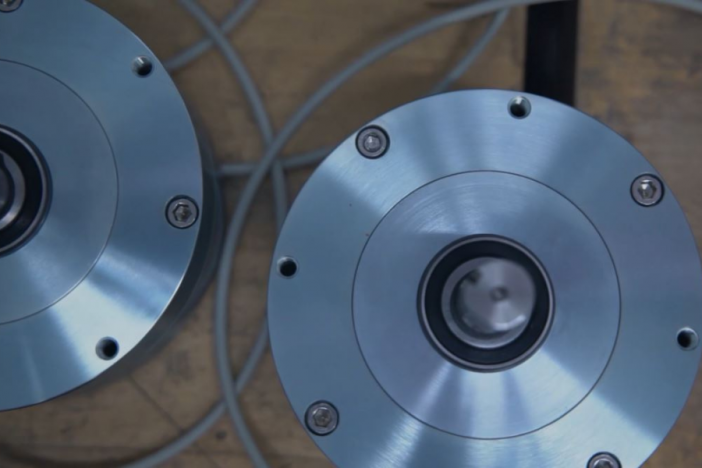

Read more BRAKES & CLUTCHES – For precision applications

Magnetic particle and hysteresis type brakes & clutches are used for precision torque & tension control. Brakes – When energized, the shaft becomes coupled to the brake’s housing. Typical applications: Brakes can provide adjustable torque for unwinding (payout) of webs, such as wire, foil & paper. Another popular application: Brakes can provide adjustable torque loads…

Read more - « Previous

- 1

- 2