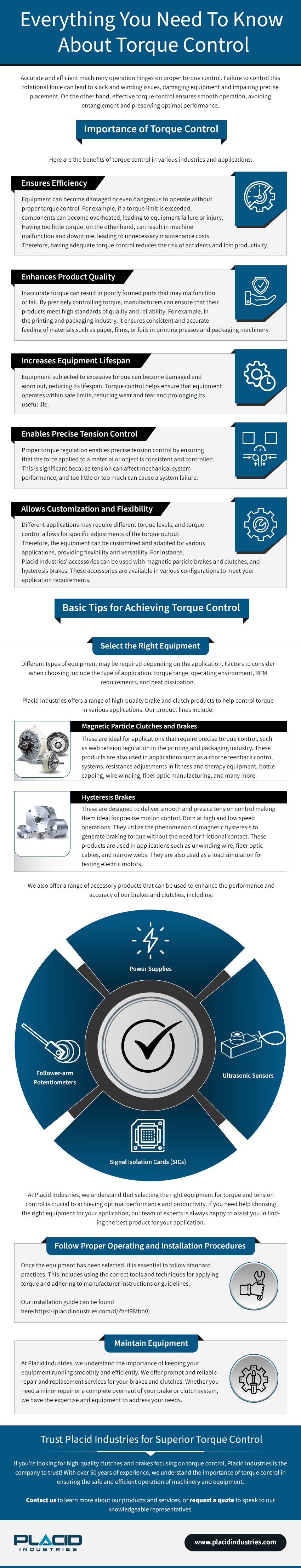

Everything You Need To Know About Torque Control

Accurate and efficient machinery operation hinges on proper torque control. Failure to control this rotational force can lead to slack and winding issues, damaging equipment and impairing precise placement. On the other hand, effective torque control ensures smooth operation, avoiding entanglement and preserving optimal performance.

This article will discuss the fundamentals of torque control by exploring its importance and basic tips for achieving it.

Importance of Torque Control

Here are the benefits of torque control in various industries and applications:

Ensures Efficiency

Equipment can become damaged or even dangerous to operate without proper torque control. For example, if a torque limit is exceeded, components can become overheated, leading to equipment failure or injury. Having too little torque, on the other hand, can result in machine malfunction and downtime, leading to unnecessary maintenance costs. Therefore, having adequate torque control reduces the risk of accidents and lost productivity.

Enhances Product Quality

Inaccurate torque can result in poorly formed parts that may malfunction or fail. By using torque control, manufacturers can ensure that their products meet high standards of quality and reliability. For example, in the printing and packaging industry, it ensures consistent and accurate feeding of materials such as paper, films, or foils in printing presses and packaging machinery.

Increases Equipment Lifespan

Equipment subjected to excessive torque can become damaged and worn out, reducing its lifespan. Torque control helps ensure that equipment operates within safe limits, reducing wear and tear and prolonging its useful life.

Enables Precise Tension Control

Proper torque regulation enables precise tension control by ensuring that the force applied to a material or object is consistent and controlled. This is significant because tension can affect mechanical system performance, and too little or too much can cause a system failure.

Allows Customization and Flexibility

Different applications may require different torque levels, and torque control allows for specific adjustments of the torque output. Therefore, the equipment can be customized and adapted for various applications, providing flexibility and versatility. For instance, Placid Industries’ accessories can be used with magnetic particle brakes and clutches, and hysteresis and are available in various configurations.

Basic Tips for Achieving Torque Control

The following are several basic techniques to follow to achieve torque control:

Select the Right Equipment

Different types of equipment may be required depending on the application. Factors to consider when choosing include the type of application, torque range, operating environment, RPM requirements, and heat dissipation.

Placid Industries offers a range of high-quality brake and clutch products to help control torque in various applications. Our product lines include:

- Magnetic particle clutchesand brakes: These are ideal for applications that require precise torque control, such as web tension regulation in the printing and packaging industry. These products are also used in applications such as airborne feedback control systems, resistance adjustments in fitness and therapy equipment, bottle capping, wire winding, fiber optic manufacturing, and many more.

- Hysteresis brakes:These are designed to deliver smooth and quiet braking action, making them ideal for precise motion control. Both at high and low speed operations. They utilize the phenomenon of magnetic hysteresis to generate braking torque without the need for frictional contact. These products are used in applications such as unwinding wire, fiber optic cables, and narrow webs. They are also used as a load simulation for testing electric motors.

We also offer a range of accessory products that can be used to enhance the performance and accuracy of our brakes and clutches, including:

At Placid Industries, we understand that selecting the right equipment for torque control is crucial to achieving optimal performance and productivity. If you need help choosing the right equipment for your application, our team of experts is always happy to assist you in finding the best product for your application.

Follow Proper Operating and Installation Procedures

Once the equipment has been selected, it is essential to follow standard practices. This includes using the correct tools and techniques for applying torque and adhering to manufacturer instructions or guidelines.

Our installation guide can be found here (https://placidindustries.com/d/?h=f98fbb0)

Maintain Equipment

At Placid Industries, we understand the importance of keeping your equipment running smoothly and efficiently. We offer prompt and reliable repair and replacement services for your brakes and clutches. Whether you need a minor repair or a complete overhaul of your brake or clutch system, we have the expertise and equipment to address your needs.

Trust Placid Industries for Superior Torque Control

If you’re looking for high-quality clutches and brakes focusing on torque control, Placid Industries is the company to trust! With over 50 years of experience, we understand the importance of torque control in ensuring the safe and efficient operation of machinery and equipment.

Contact us to learn more about our products and services, or request a quote to speak to our knowledgeable representatives.