Hysteresis Brakes

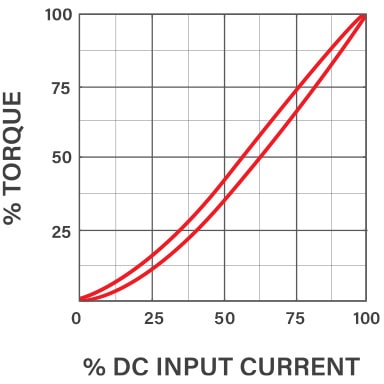

Torque is proportional to input current, and independent of RPM. Torque is especially smooth, even at near-zero RPM. Also good for light tension / high RPM applications, due to good heat dissipation ratings. All models except H3 have the Cog-Buster which keeps slip torque smooth.

- Producing tension for unwinding wire, fiber optic cable, and narrow webs.

- Load simulation for testing electric motors.

- Applications requiring light tension / wide RPM capability.

- Is proportional to input current.

- Is independent of RPM.

- Is especially smooth, even at near-zero RPM.

- Imperial Unit – Torque Range: 0.04 -2.5 to 7-250 (oz-in)

- Metric Unit – Torque Range: 0.03-1.77 to 4.3-177 (Newton-cm)

- Torque is produced without friction plates or magnetic particles. Life is extremely long, even at high RPM, because torque is produced magnetically across an air gap.

- Slip torque is extremely smooth, even down to zero RPM. Placid Industries' Cog-Buster automatically de-cogs the brake within one revolution of the shaft.

- With no electrical excitation, the shaft freely rotates.

- With electrical excitation, the shaft becomes coupled to the case.

- While the load torque is less than the output torque, the shaft won’t rotate continuously.

- When the load torque is increased, the brake will slip smoothly at the torque level set by the coil input current.

- Not suitable for precise positioning applications

Mounts in any orientation.

Datasheet Key

Regarding Shaft Styles:

1 = Solid Shaft Out 1 Side (Bearing Side) Only

2 = Solid Shaft Out 2 (Both) Sides

3 = Solid Shaft Out Cover Side Only

View in metric

Hysteresis Brakes - up to 250 oz.-in. (1.77 Nm)

| Model | Torque Range | Input Electric Power (watts) | Shaft Inertia (lb-in-sec2) | Slip Heat Dissipation Cover On (watts) | Slip Heat Dissipation Cover Off (watts) | Max Overhung Load (lbs) | Maximum RPM | Weight (lbs) | Shaft Style(s) | |

|---|---|---|---|---|---|---|---|---|---|---|

| H3 | 0.04 - 2.5 oz.-in. | 2.5 | 3.8 x 10-6 | - | 5 | 1 | 10,000 | 0.23 | 1, 2, 3 | Details |

| H11 | 0.3 to 11 oz.-in. | 2 | 36 x 10-6 | 9 | 15 | 4 | 9,000 | 0.7 | 1, 2, 3 | Details |

| H35 | 0.6 to 35 oz.-in. | 6 | 92 x 10-6 | 15 | 25 | 5 | 8,000 | 2 | 1, 2, 3 | Details |

| H85 | 3 to 85 oz.-in. | 5 | 560 x 10-6 | 35 | 60 | 40 | 6,000 | 4.5 | 1, 2, 3 | Details |

| H140 | 4 to 140 oz.-in. | 7 | 970 x 10-6 | 45 | 75 | 40 | 5,000 | 6 | 1, 2, 3 | Details |

| H250 | 6 to 250 oz.-in. | 7 | 290 x 10-5 | 65 | 110 | 50 | 5,000 | 9 | 1, 2, 3 | Details |

See data sheet for heat dissipation info.

Mounting holes - Standard: Imperial (inch), Optional: Metric